Improving Scope 1 Emissions: Overview of Our Factory CO₂-Reduction Projects

Big changes have been happening at Südzucker Sugar Division – not just in strategies or roadmaps, but right where it counts: inside our factories. We’re on a mission to cut down CO₂ emissions across the board. And that starts, at our production sites. Each one is contributing in its own way – and together, they’re pushing us forward toward a more sustainable business.

These CO₂ reduction projects are a key part of Südzucker Sugar Division’s sustainability strategy. By further investing in energy efficiency, electrification of our processes and the use of natural gas or biomethane, we are actively working toward Südzucker Group’s validated Science-Based Targets, aiming to reduce Scope 1 and 2 emissions by 50.4% by 2030, starting from a base year 2018. Our projects also contribute to reduce our Scope 3 emissions – i.e. the emissions generated in our supply chain.

At Südzucker Sugar Division, our climate goals aren’t abstract. They’re becoming tangible – in pipes, pumps, valves, and clever processes across our production sites. Let’s take a closer look at some of the most impactful CO₂-reduction projects we’ve recently implemented across our production sites:

August 2024

Sugar Factory in Strzelin, Poland : Transition from Coal to Natural Gas

In Strzelin, Poland, a major step has been taken on our way from replacing coal with natural gas, during the 2024/2025 campaign. It has allowed us to cut around 5,000 tons of CO₂. Another investment of the modernization works is the expansion of the biogas plant, which is an integral part of the energy transformation, allowing next campaign to run already on 80% of biogas and 20% on natural gas. A serious and meaningful investment.

If you’d like to learn more, feel free to check out our blog post.

October 2024

Sugar Factory Ochsenfurt, Germany: Boiler Conversion to Natural Gas

In Ochsenfurt, Germany, we’ve taken a major step on our decarbonisation journey: the entire site has transitioned from hard coal to natural gas. At the heart of this transformation is our newly converted BABCOCK boiler, now running on natural gas and delivering 100 tons of steam per hour at 80 bar. This single unit covers around 70% of the sugar factory’s energy needs and is complemented by an additional gas-fired boiler.

We’re cutting 28,000 tons of CO₂ emissions per year – a massive reduction that supports our path to climate neutrality.

For more detailed information, feel free to check out our LinkedIn post.

December 2024

Tienen, Belgium: Boiler House Modernization and Green Gas Injection

Boiler House Modernization: Our boiler house at Raffinerie Tirlemontoise has been completely upgraded with two new steam boilers now boasting a 98% efficiency. By incorporating innovations such as heat recovery from exhaust gases, high-efficiency pumps, and enhanced insulation, we’re reducing CO₂ emissions by more than 7,500 tons annually. The new system is also designed with the future in mind, capable of operating on electricity and hydrogen.

Biomethane Injection: Instead of flaring biogas from our wastewater treatment plant, we now upgrade it to biomethane. This renewable gas will be injected into the public grid by 2025, supplying up to 500 households with sustainable energy.

Read more about it in our LinkedIn post here.

March 2025

Tienen, Belgium: Industrial Heat Pump Installed at Raffinerie Tirlemontoise

In Tienen, Belgium, we’re turning up the heat – and doing so efficiently. A new high-temperature industrial heat pump has been successfully installed. This innovative system marks a major leap forward in energy-efficient food production.

With a thermal capacity of 4 megawatts and the ability to generate heat of up to 140°C, the new heat pump captures and reuses waste heat from our production processes. This boosts our energy efficiency and significantly reduces our environmental footprint, helping us to avoid up between 3,000 and 3,500 tons of CO₂ emissions annually.

Don’t miss this LinkedIn article if you’re interested in exploring this further.

March 2025

Étrépagny Sugar Factory of Saint Louis Sucre, France: Heat Recovery for Beet Preheating

A newly commissioned mixing system for beet pulp now enables us to recover heat from the production process and reuse it to preheat sugar beets before extraction. This smart use of existing energy significantly improves the plant’s energy performance and reduces our environmental impact.

Thanks to this innovation, we’re avoiding the emission of 9,000 tons of CO₂ every year – a major step forward in our decarbonization journey.

You’ll find a more in-depth explanation in this LinkedIn article.

April 2025

Sugar Factory in Zeitz, Germany: New Thick Juice Dissolver Cuts Energy Use

Here we have introduced a new thick juice dissolver. Previous method of sugar dissolution: Before the implementation of the new thick juice dissolver, the raw and by-product sugars obtained during crystallization were dissolved with condensate water and then recrystallized. The water used to dissolve the sugar had to be reevaporated. Now, with the new thick juice dissolver, most of the water is replaced by thick juice, eliminating the need for evaporation and thus saving primary energy.

This upgrade is saving us around 20,000 kWh of energy each year. Additionally, we’re cutting about 7,500 tons of CO₂ annually. The secret lies in smarter water use: less water in the process means less energy needed to heat it.

Read more on Linkedin here.

June 2025

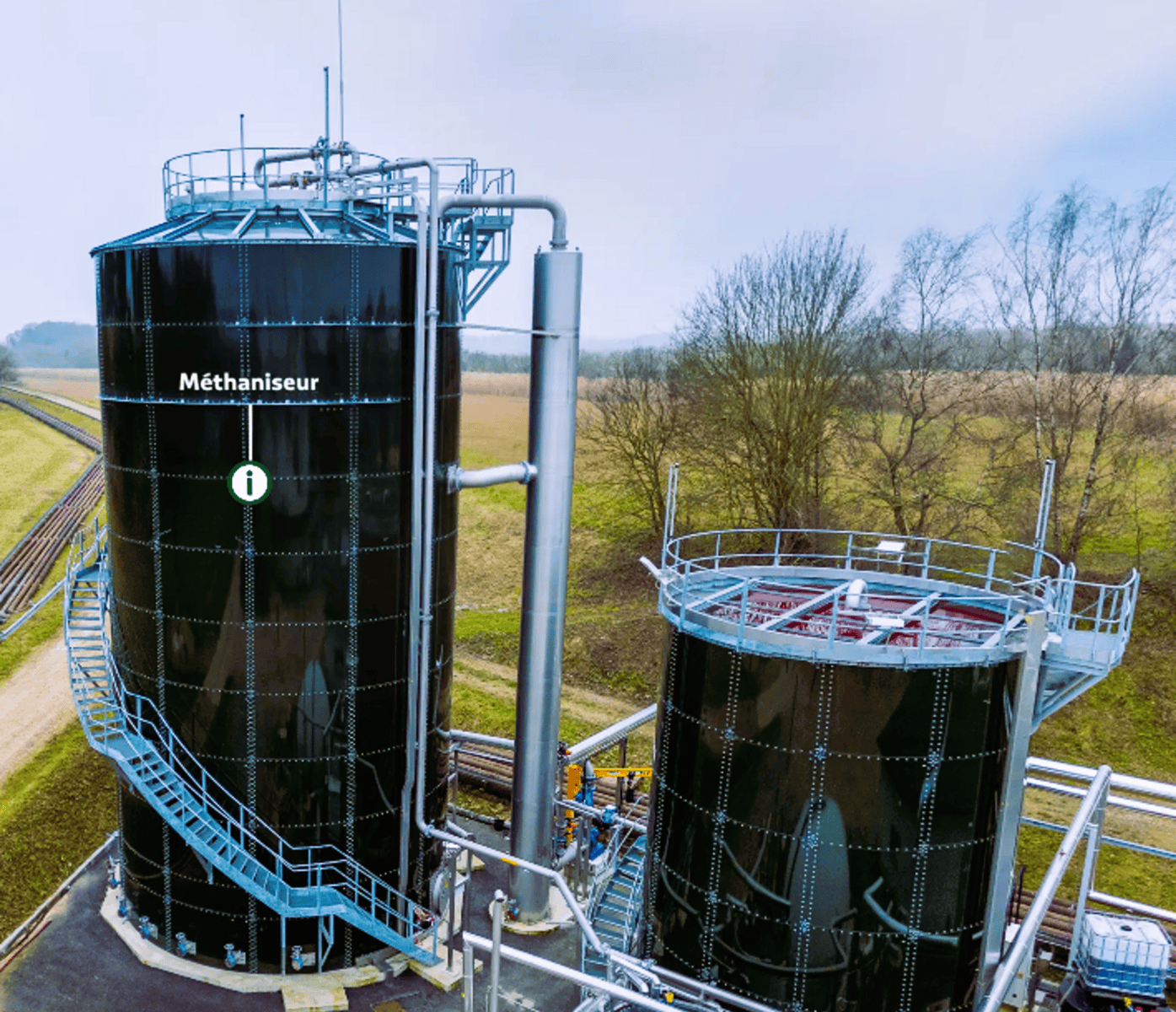

Étrépagny Sugar Factory of Saint Louis Sucre, France: Methanisation Boosts CO₂ Reduction

At our Saint Louis Sucre sugar factory in Étrépagny, France, we’ve added another building block to our decarbonization journey: a large-capacity methaniser, commissioned in December 2024. This new unit complements the existing wastewater treatment plant and produces biogas from sugar beet washing water – a clear win for both energy and environmental performance.

What this means in numbers:

- 1,000 tons of CO₂ emissions avoided annually

- Up to 3% of the factory’s gas demand is now covered by biogas produced on-site

This is a great example of how we combine resource circularity with climate action. The methanisation process not only reduces fossil fuel demand but also helps improve water quality – increasing the proportion of treated water that can be safely returned to the environment.

Feel free to check out this article on LinkedIn.

June 2025:

Roye Sugar Factory of Saint Louis Sucre, France: Natural Gas Powers Sustainable Pulp Drying

At our sugar factory in Roye, operated by Saint Louis Sucre, we’ve made a smart switch that’s been paying off for two years now: the pulp dehydration unit has been running on natural gas since the 2023 campaign. This measure has significantly reduced our environmental footprint – and it’s helping us make the most of every part of the sugar beet.

Why it matters:

- 7,000 tons of CO₂ emissions avoided every year

- Dehydrated beet pulp – a valuable by-product – is used as animal feed

- Reduced atmospheric emissions compared to previous fossil-based systems

By moving from conventional fuels to natural gas, we’ve improved both the environmental and operational performance of one of our key side-stream processes. This is an important step in Saint Louis Sucre’s and Südzucker Sugar Division’s climate strategy, contributing directly to our Scope 1 emission reductions – and supporting our customers’ Scope 3 goals.

Check out our LinkedIn post.

Subscribe to our quarterly newsletter to make sure you never miss any news.

Each project brings us one step closer to Südzucker Group’s vision: Net Zero by 2050. Taken together, these local changes make a real, measurable difference. And we’re not stopping here. From upgrades to overhauls, every action we take helps build a cleaner sugar value chain.

For you, our customers, this means more than just buying sugar. It means partnering with a supplier that actively supports their own climate goals. As sustainability reporting becomes more rigorous and transparent, companies are increasingly accountable for the emissions embedded in their supply chains. By reducing our own footprint, we also help reduce your Scope 3 emissions – making it easier for you to meet your targets and to respond to growing stakeholder expectations.

Would you like to learn more about our specific sustainability commitments, initiatives?

Visit our “Emissions Reduction” site