to sheets

BeetKraft®: paper and packaging

from sugar beet

What if the packaging material of the future came straight from the local neighbourhood – produced regionally in southern Germany, from natural raw materials and with high stability? With BeetKraft®, we are presenting a fibre for the paper and packaging industry that represents a genuine alternative to traditional wood fibres. Using a patented refinement process, we develop a high-performance fibre from a by-product of sugar production.

Consistent quality, fast and continuous availability, easy integration into existing production processes and low price volatility are important criteria, especially for alternative fibres and packaging materials, in order to justify the (partial) replacement of classic wood-based pulp.

Discover BeetKraft®, the pioneering solution for paper and packaging – made from sugar beet.

Responsible. Reliable. Strong.

BeetKraft® offers various advantages for paper producers, converters and brand manufacturers

High Paper Strength

BeetKraft® increases the stability of packaging by up to 11% – depending on the type of packaging. At the same time, it makes it possible to reduce the overall grammage without compromising on packaging quality, functionality or an appealing, authentic packaging design.

Reliable, Regional Availability

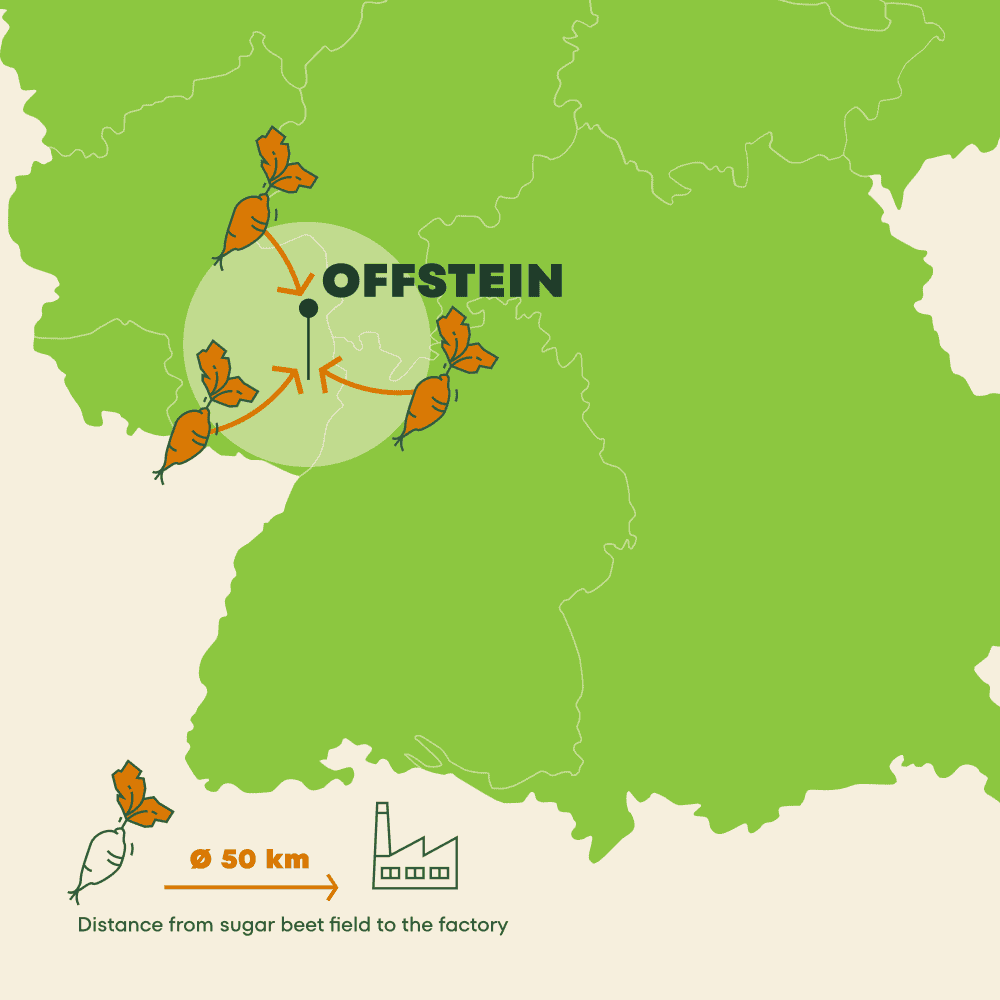

The regional procurement of sugar beet in southern Germany and production in Offstein with year-round availability keeps supply chains short and short-term delivery options open – without the risk of reduced efficiency due to a lack of raw materials on a paper producer’s side.

Natural Raw Material

BeetKraft® is produced from southern German sugar beet in a patented refining process as part of normal sugar production. Sugar beet as part of the crop rotation of regenerative agriculture offers many advantages for healthy soils.

Powerful innovation

from sugar beet

Sustainability, functionality and an appealing look are just three of the decisive criteria by which packaging solutions are increasingly being measured by consumers. The demand for alternative packaging materials is constantly growing. However, replacing traditional cellulose without compromising paper production or the quality of the end product is a challenge for many manufacturers.

BeetKraft® is the result of intensive innovation work that enables us to process sugar beet by-products (dried sugar beet pulp) into a pulp for paper and cardboard packaging. As a future-oriented alternative to traditional wood pulp, BeetKraft® enables up to 40% of wood fibres (NBSK/SBSK) to be easily replaced in the paper formulation.

In cooperation with the PTS – Institut für Fasern & Papier gGmbH in Heidenau – the material properties of BeetKraft® and the suitability of the material as an alternative pulp for the production of different paper qualities were investigated and evaluated.

After material screening on a laboratory scale, tests were carried out with various materials in combination with primary and secondary fibres to produce different paper qualities on the PTS test paper machine as well as production in a paper mill.

The paper produced was processed on a trial basis for the manufacture of packaging for sugar products after a food safety declaration had been drawn up.

BeetKraft® is versatile and suitable for various paper and packaging solutions.

Kraft Paper

BeetKraft® gives kraft paper high strength and durability. At the same time, the total grammage can be reduced depending on the application.

Cartonboard

The use of BeetKraft® ensures stable, high-quality cartonboard that is perfect for displays and product packaging.

Containerboard

BeetKraft® improves or maintains the stability of containerboard and offers an ideal solution for the production of robust corrugated packaging and transport boxes.

The short delivery routes and easy integration into existing processes make BeetKraft® the ideal choice.

- Increased SCT value: increase in stability by 10–11% depending on the end application.

- Material reduction possible: potential saving of NBSK/SBSK in production.

- Year-round availability: continuous production reliability without interruptions.

- Short delivery times: no need for long storage or stockpiling.

- Scalable and industrially viable: suitable for production in large quantities.

- Chemical-free production process: beet pulp is refined into BeetKraft® fibre without the use of chemicals.

- Stable paper production: consistent quality and reliable production processes.

- Technical advice: support from Südzucker for sampling, testing and productive use available.

- Industrially tested: tested on demo plants and on an industrial scale.

- Regional cultivation: short delivery routes and regional sourcing of raw materials.

- Renewable raw material: sugar beet is an annual plant, grown in crop rotation with benefits for healthy soils.

- FSC certification: no danger of losing FSC certifications for the end product.

- Food-compliant: safe for contact with dry, non-greasy foodstuffs.

- Recyclable: fully recyclable.

BeetKraft® offers a competitive fibre solution that shows great performance in existing processes.

- Consistent and high print quality: BeetKraft® offers consistently high print quality.

- Year-round availability: ensuring continuous production.

- Short delivery times: no need for extensive warehousing or stockpiling.

- Scalable and industrial-grade: suitable for production in large quantities.

- Chemical-free production process: beet pulp is refined into BeetKraft® fibre without the use of chemicals.

- Stable paper processing: consistently high quality in paper processing and production.

- Technical advice: support for sampling and test productions by Südzucker possible.

Surprise your customers with an innovative packaging solution.

- Natural look: authentic feel and appealing effect on the consumer.

- Consistent print quality: consistent, high-quality print results.

- Increased stability: more strength with the potential to save material at the same time.

- Regional cultivation: BeetKraft® comes entirely from German cultivation.

- FSC-certifiable: packaging remains FSC-certifiable.

- Recyclable: fully recyclable.

- Food-compliant: safe for contact with dry, non-greasy foodstuffs.

Latest Download

Where Does BeetKraft® Come From and How is it Produced?

BeetKraft® is a product made from sugar beet pulp during the annual sugar production. In addition to being used as animal feed and for energy recovery, it is now also refined in a patented process and converted into a high-quality fibre for the paper industry.

The BeetKraft® pulp has a brownish colour due to its origin, which ultimately gives the final kraft paper, cardboard or containerboard a natural-looking colour.

100% of German Origin

On average, our sugar beet comes from within a 50 km radius of our factories, which enables flexible and fast delivery throughout Germany. As sugar beet is a renewable raw material, is cultivated in crop rotation and is not a monoculture, it represents a major advantage for agriculture in addition to its complete usability.

Sugar beet cultivation is continuously optimised for a more sustainable farming approach. We only use non-genetically modified sugar beet varieties and are working on innovative solutions to improve weed control, fertilisation, plant protection and biodiversity.

AT SÜDZUCKER

Your contact person

Are you interested in BeetKraft® for your paper and packaging solutions or for specific applications?

We are happy to support you in the development of new concepts and creative ideas with fibres from sugar beet – please contact me!

Marcus Reuter – Head of Co-Products

Faq

The BeetKraft® fibres are firmly anchored in the paper structure; there are no impairments due to fibre tears or dusting during processing. The fibre structure is not weakened or negatively influenced by the use of BeetKraft®. There are no negative side effects during subsequent paper processing.

In extensive test series to date, we have not noticed any negative effects with regard to strength values. We have noticed effects on air permeability and roughness. Please contact us for more detailed information.

We have noticed an increase in roughness in previous productions. The air permeability also increases. Due to the unbleached fibre character, the packaging has a more natural-looking colour. A high-quality print image is still maintained. The intensity of the colour values depends on the individual fibre treatment.

BeetKraft® is currently packaged and delivered in big bags of various heights. We are working on other forms of packaging. We will find an individual solution for your BeetKraft® application. Please do not hesitate to contact us.

BeetKraft® is characterised by the fact that the use and substitution of virgin fibres does not impair the paper properties in terms of strength. There are no negative side effects during processing.

We can offer market-relevant quantities with our production plant. Production capacity will be scaled up in the medium term. Due to the drying and fibre treatment method, the fibre supply is guaranteed all year round and with consistent quality.

The full potential of BeetKraft® can be used with the familiar paper processing methods of defibration and refining. Individual support is required for the first applications.

The sugar beet pulp was previously also marketed as animal feed or for energy recovery, among other things.

The BeetKraft® technology now makes it possible for us to produce high-quality virgin fibres for paper production from the sugar beet pulp. This additional recycling option further secures the previously closed recycling loop.