Granulated White Sugars

Our Granulated White Sugar is an all-purpose sugar. It is a single-ingredient foodstuff and consists of pure, free-flowing crystals of sucrose with a white appearance. Whether used in beverages, baked goods, or pharmaceutical formulations, our sugar portfolio is designed to address all of your sugar needs at the highest Standard of quality. We therefore offer three qualitative grades of granulated white sugar in bulk and in various granular sizes to meet specific product requirements such as:

- Extra White Sugar – For products demanding extreme whiteness and brilliance

- White Sugar High Grade – to deliver less colour and excellent filterability in beverages

- White Sugar – to easily add basic sweet taste with the most standard quality

General Benefits

- Can be used for many applications in the food and beverage industry

- Adds a sweet and pure taste

- Provides several functional benefits (e.g. enhances colour and flavour, increases shelf-life, adds viscosity)

- Serves as a bulking agent in food, contributing to its texture and mouthfeel

Our White Sugar Portfolio

Product characteristics and Applications

We produce our ‘Extra White Sugar’, ‘White Sugar High Grade’ and ‘White Sugar’ exclusively from sugar beets. Their individual characteristics make them ideal for different applications, including cakes, biscuits, pastries, but also dairy products, fruits preparations, etc.

| Extra White Sugar | White Sugar High Grade | White Sugar | |

| Benefits |

|

|

|

| Applications |

|

|

|

Download Product Specifications

Certifications

At Südzucker, we are strongly committed to complying with recognized certification standards in order to achieve the highest quality for our products.

To find the certification documents relevant to you, please use our document search, which allows you to search by document type and country of origin of Südzucker products.

Calibrated White Sugars for your needs

As a leading white sugar manufacturer, we also offer custom sugar solutions to meet your highest industry standards.

- In EU2-grade quality

- Customised crystal mixes / bespoke blends can be developed

Organic White Sugar

We also offer White Sugar, in certified-organic quality. Our organic beet sugar is available with the following organic certifications: EU Bio, Naturland, BioSuisse and Bioland.

Learn more about Südzucker’s

Pharmaceutical Standards

We produce our Extra White Sugar according to the highest food quality standards and we can propose you references compliant to the sucrose monograph of the European pharmacopoeia.

Available Grain Sizes White Sugar

We offer these products in a wide variety of grain sizes that provide unique functional benefits which make them particularly suitable for specific applications, whether in the baking, confectionery, or beverage industry. Our granulated white sugars are available in five grain sizes: Standard, Coarse, Medium, Fine, Extra Fine. We can also supply additional grain sizes upon request.

| Type of designation | Symbol | Mean aperture (in mm) |

|---|---|---|

| Standard | S | 0.40 – 1.00 |

| Coarse | C | 1.00 – 1.60 |

| Medium | M | 0.60 – 1.00 |

| Fine | F | 0.40 – 0.65 |

| Extra Fine | XF | 0.20 – 0.40 |

White Sugar Grain Size Usage by Application

| White Sugar grain size | |||||

|---|---|---|---|---|---|

| Standard | Coarse | Medium | Fine | Extra Fine | |

|

Biscuits & Baked Goods

(Special case: Decoration) |

|||||

|

Sugar Confectionery

(Special case: Decoration) |

|||||

Granulated White Sugars

Packaging Storage & Shelf Life

| Packaging type | Packaging unit (in kg) |

| PE Bag | 20, 25 |

| Paper Bag | 20, 25 |

| Big Bag | 1000 |

| Bulk |

If you are looking to buy white sugar in bulk (20 kg, 25 kg, or more) for your applications and want to know which packaging types and packaging units are available for your desired product, please contact us.

Granulated White Sugar has no best-before date but should be stored above 10°C, below a relative humidity of around 65 %, and kept away from odorous materials. Under these conditions, our Granulated White Sugars will keep their specific properties and are indefinitely storable.

Do you want more information on our crystalline white sugars? Are you interested in special granulometries, qualities?

Do you have further questions or need support to select the right crystalline sugar product?

Daniel Neu, Product Manager White Sugar, Extra White Sugar, White Sugar High-Grade

Sugar Processing

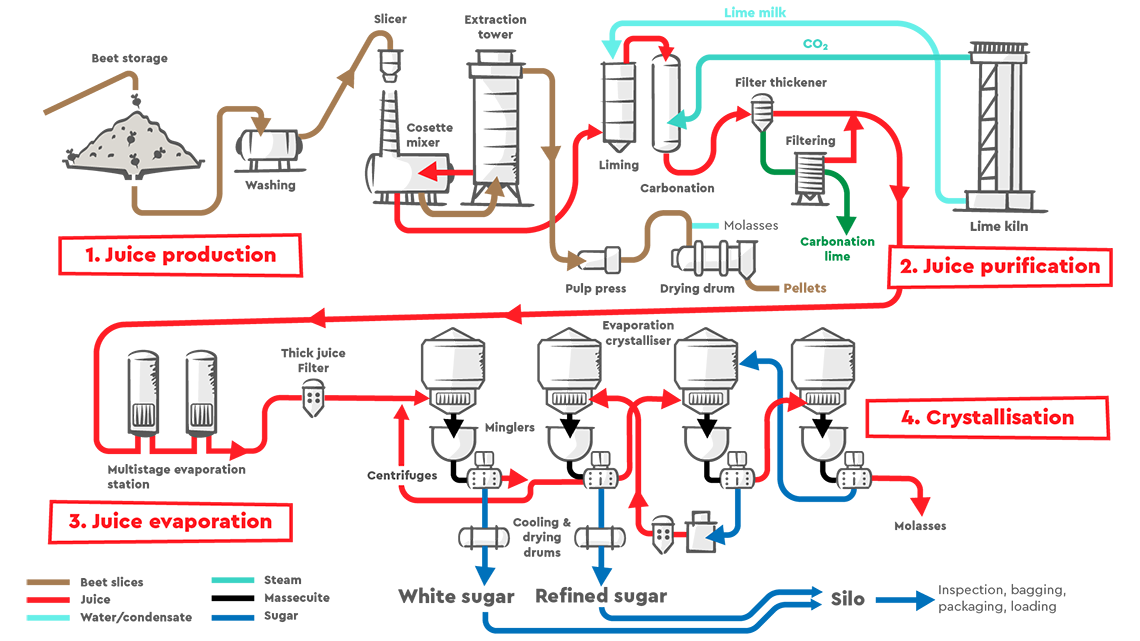

Did you know that it takes just 8 hours to produce shimmering white sugar crystals from a sugar beet… field to factory?

Let’s have a closer look at the process:

Sugar beet harvesting begins in September, “the campaign”. We take samples from each load of beet delivery to determine e.g. sugar content and to analyze the amount of soil left on the beets. Once the beets are offloaded they are thoroughly washed and are sent directly to the processing line or to the storage facility.

The sugar beets are sliced into thin strips known as cossettes, pre-heated in a cossette scalder and are then sent to an extraction tower. Water at 70°C is poured through the device to extract the sugar and produce raw juice. The used cossettes are dried by means of screw presses and hot air.

A lime kiln is used to produce the natural substances lime and carbon dioxide, which are added sequentially to the raw juice to bind and precipitate out the non-sugar impurities. A clear, thin juice with a sugar content of approximately sixteen percent remains.

The thin juice is concentrated by heating to make a thick golden-brown juice with a sugar content of about sixty-seven percent.

The thick juice is boiled until sugar crystals are formed, which are a glowing golden colour because they are covered in syrup. The syrup is separated from the crystals in a centrifuge. Hot water is used to rinse off any residual syrup. The remaining sugar crystals are clear as glass, and the light refracted from them is white as snow. The sugar is dissolved and re-crystallized to produce refined sugar – sugar that is extremely pure.

The finished beet sugar is dried, cooled and stored in silos, and is subsequently withdrawn and further processed or packed. As a white sugar manufacturer for B2B, over eighty percent of our sugar production is sold for industrial use with the balance sold to retail.